Open Source Tools Provide An Economic Advantage For Science

Review finds significant cost savings when using free and open source scientific hardware over proprietary equivalents.

Joshua PearceFree and open source software (FOSS) and the distributed digital manufacturing of free and open source hardware (FOSH) have shown great promise for developing custom scientific tools. For some time now, FOSH has provided scientists a high return on investment.

Joshua PearceFree and open source software (FOSS) and the distributed digital manufacturing of free and open source hardware (FOSH) have shown great promise for developing custom scientific tools. For some time now, FOSH has provided scientists a high return on investment.

In fact, my previous research in the Open Source Lab reported substantial economic savings from using these technologies. However, the open source design paradigm has since grown by orders of magnitude; now, there are examples of open source technology for science in the vast majority of disciplines, and several resources, including the Journal of Open Hardware, are dedicated to publishing them.

It is possible that the savings observed from early scientific open source technologies may have been isolated to special cases where the market left opportunities open or to "low-hanging fruit" that would no longer hold up today.

This begs several questions:

- What if we identified all the good FOSH opportunities in the early 2000s?

- Do the tremendous economic savings observed then for open source hold today?

- Are scientists still saving money with open source technologies?

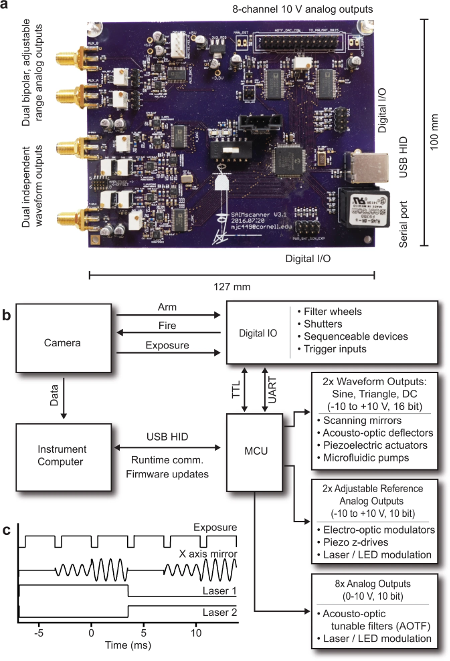

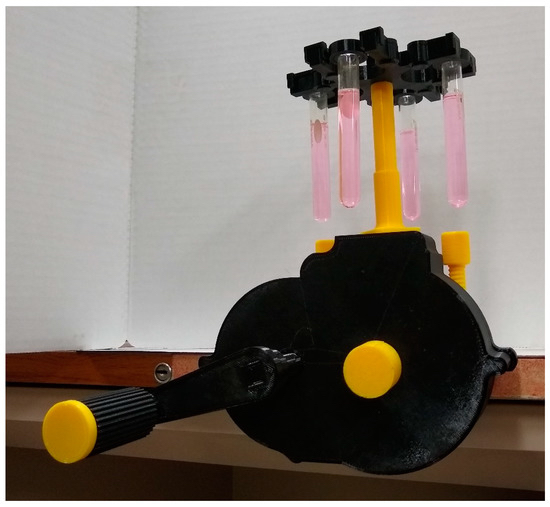

Open source 3D printable centrifuge (Salil S. Sule, Aliaksei L. Petsiuk, Joshua M. Pearce, CC BY 4.0)To answer these questions, I did a study, recently published as Economic savings for scientific free and open source technology: A review, that evaluated free and open source technologies compared to proprietary, functionally equivalent tools.

Open source 3D printable centrifuge (Salil S. Sule, Aliaksei L. Petsiuk, Joshua M. Pearce, CC BY 4.0)To answer these questions, I did a study, recently published as Economic savings for scientific free and open source technology: A review, that evaluated free and open source technologies compared to proprietary, functionally equivalent tools.

The study evaluated FOSH in two databases: HardwareX, a journal dedicated to FOSH, and PLOS Open Source Toolkit, which houses curated FOSH articles from Public Library of Science One and a wide range of specialty journals.

My study identified two enabling innovations that offer scientists and engineers a new method of distributed digital manufacturing and that provide greater than 90% cost savings:

- Open source electronics like the Arduino prototyping platform

- The open source self-replicating rapid prototyper (RepRap) project that provides open source 3D printing

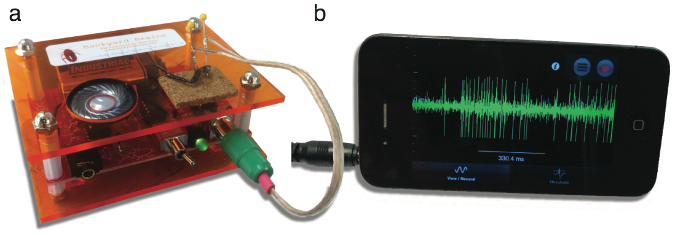

SpikerBox, a low-cost, open source neuroscience tool for schools. (Timothy C. Marzullo and Gregory J. Gage, CC BY 4.0)Arduino and related electronics are useful for automating the design of a wide range of scientific equipment. Meanwhile, the RepRap 3D printer technology can make bespoke mechanical components for developing tool libraries for optics or syringe pumps as well as becoming scientific tools themselves in the form of microfluidics prototypers, chemical handling systems, and 3D microscopes.

SpikerBox, a low-cost, open source neuroscience tool for schools. (Timothy C. Marzullo and Gregory J. Gage, CC BY 4.0)Arduino and related electronics are useful for automating the design of a wide range of scientific equipment. Meanwhile, the RepRap 3D printer technology can make bespoke mechanical components for developing tool libraries for optics or syringe pumps as well as becoming scientific tools themselves in the form of microfluidics prototypers, chemical handling systems, and 3D microscopes.

My review finds overwhelming evidence that, for a wide range of scientific tools, open source technologies provide economic savings of 87% compared to equivalent or lesser proprietary tools.

These economic savings increased to 89% when using Arduino technology and to 92% when using RepRap-class 3D printing. By combining Arduino and open source 3D printing, the savings averaged 94% for free and open source tools over commercial equivalents.

These results provide strong evidence in favor of providing financial support for developing open source hardware and software for the sciences. Why would governments fund the development of proprietary tools if they provide less flexibility for scientists and cost so much more?

Why buy proprietary equipment when you can get custom equipment that you have complete control over for only a fraction of the cost? Given the overwhelming economic advantages of free and open source technologies, it appears financially responsible to divert funding from proprietary scientific tools in favor of FOSH.

About the author

Joshua Pearce - Dr. Joshua Pearce is cross appointed as a Professor in the Materials Science & Engineering and the Electrical & Computer Engineering at Michigan Tech. He currently runs the Michigan Tech in Open Sustainability Technology (MOST) group. He is the author of the Open Source Lab. His research focuses on open and applied sustainability, which is the application of science and innovation to ensure a better quality of life for all, now and into the future, in a just and equitable manner, whilst...More about me

Attribution

This article was published in Opensource.com. It is republished by Open Health News under the terms of the Creative Commons Attribution-ShareAlike 4.0 International License (CC BY-SA 4.0). The original copy of the article can be found here.

- Tags:

- 3D microscopes

- Aliaksei L. Petsiuk

- bespoke mechanical components

- chemical handling systems

- cost savings

- custom scientific tools

- distributed digital manufacturing

- FOSH high return on scientific investment

- Free and open source hardware (FOSH)

- free and open source software (FOSS)

- Gregory J. Gage

- HardwareX

- Joshua Pearce

- Journal of Open Hardware

- Marshall J. Colville

- Matthew J. Paszek

- microfluidics prototypers

- open health

- Open Medicine

- open science

- Open source 3D printable centrifuge

- open source 3D printing

- open source design paradigm

- open source electronics

- Open Source Lab

- open source neuroscience tool

- open source scientific hardware

- open source self-replicating rapid prototyper (RepRap) project

- open source technology

- open source tools

- Opensource.com

- PLOS Open Source Toolkit

- proprietary scientific hardware

- Public Library of Science One

- Salil S. Sule

- Sangwoo Park

- scientific equipment

- scientific open source technologies

- SpikerBox

- Timothy C. Marzullo

- tool libraries for optics

- tool libraries for syringe pumps

- Warren R. Zipfel

- Login to post comments